Client

A leading diesel engine manufacturer

Goal

Reduce bottlenecks on the production line that arise from last-minute changes to orders and ensure compliance with build instructions

Tools and technologies

Windows, SQL Server, C#, .NET, ESB, HTML5, Angular, GitHub, JIRA, Visual Studio, and WebStrom

BUSINESS CHALLENGE

A diesel engine manufacturer based in Detroit faced frequent production delays. The cause of the inefficiency was its build book system. The manufacturer used a printed build book to communicate the specifications of the engine being built to the production floor. But, often after the book was sent to the shop floor, the manufacturer had to make changes to specifications. In such cases, those working on the production line would not be able to use the printed build book. Waiting for a reprinted book would halt production. As a result, the changes were usually communicated outside the manual and assumed to be followed. If the new specifications weren’t followed, they would be discovered only in quality assurance, leading to a loss of time and dollars.

SOLUTION

The client wanted a solution to resolve bottlenecks created by the printed build book and ensure compliance with build instructions. Ideally, the build book is dynamically pushed onto a handheld device assigned to the shop floor. The system would allow managers to update the specifications in the build book on the fly and alert the production team to the changes.

The device would also communicate the status of production to managers. For example, they would know which work center is working on an engine so that relevant pages of the build book could be updated and displayed to those work centers.

Iris custom-built an application that allowed real-time updates of the build book. It was designed to push the build book to work center operators on V10 devices (RFID transponders) with screen sizes ranging from 3 inches to 10 inches. The solution included a consolidated dashboard that provided the management near real-time visibility of work centers and the status of the engine production.

OUTCOMES

During Phase 1 of the project, we deployed 250 V10 devices. After a pilot run of four weeks, the client stopped printing build books; the handheld devices with our application were a superior alternative. The solution helped eliminate printing costs and allowed the manufacturer to accommodate last-minute changes in specifications without disrupting production.

Related Stories

Gen AI interface enhances API productivity and UX

Integrating Generative AI technology into a leading logistics provider’s developer portal reduces API onboarding to 1-2 days.

Data warehouse enhances client communications

Bank’s multi-channel client communications and portfolio management capabilities improved with investment data warehouse

Cloud Data Lakehouse for Single Source of Truth

Transformation of data and BI applications to MS Azure cloud deliveres “Order to Cash” sales analytics on cloud for a life sciences company.

Contact

Our experts can help you find the right solutions to meet your needs.

Get in touchAn agile sprint for financial data

Client

Among the world’s largest manufacturers of sportswear, the client sells its products in more than 120 countries and employs more than 13,000 people.

Goal

To significantly reduce turnaround time and ease associated with report creation.

Tools and technologies

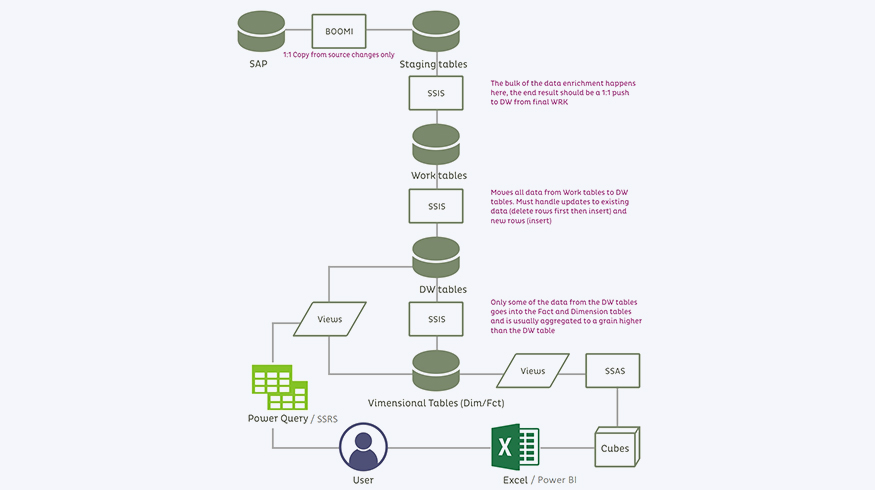

Microsoft SQL Server’s Analysis Services (SSAS), Microsoft SQL Server Integration Services (SSIS), Microsoft SQL Server Reporting Services (SSRS), Boomi AtomSphere, and Power BI.

BUSINESS CHALLENGE

SOLUTION

OUTCOMES

Related Stories

Data warehouse enhances client communications

Bank’s multi-channel client communications and portfolio management capabilities improved with investment data warehouse

Cloud Data Lakehouse for Single Source of Truth

Transformation of data and BI applications to MS Azure cloud deliveres “Order to Cash” sales analytics on cloud for a life sciences company.

Platform re-engineering for operational efficiency

A leading brokerage bank improved operational efficiencies with data extraction platform modernization.

Contact

Our experts can help you find the right solutions to meet your needs.

Get in touchCompany